Printing Barcode Labels Is Easy and Increases Your Business Efficiency

BARCODE LABELING BASICS FOR YOUR BUSINESS

Barcodes have become a necessity in doing business today. For one, it is critical for your organization to keep accurate data of all inventory, shipments and assets inorder to be more productive and profitable. Read about barcodes, its hostory and how and why they evolved and uses.

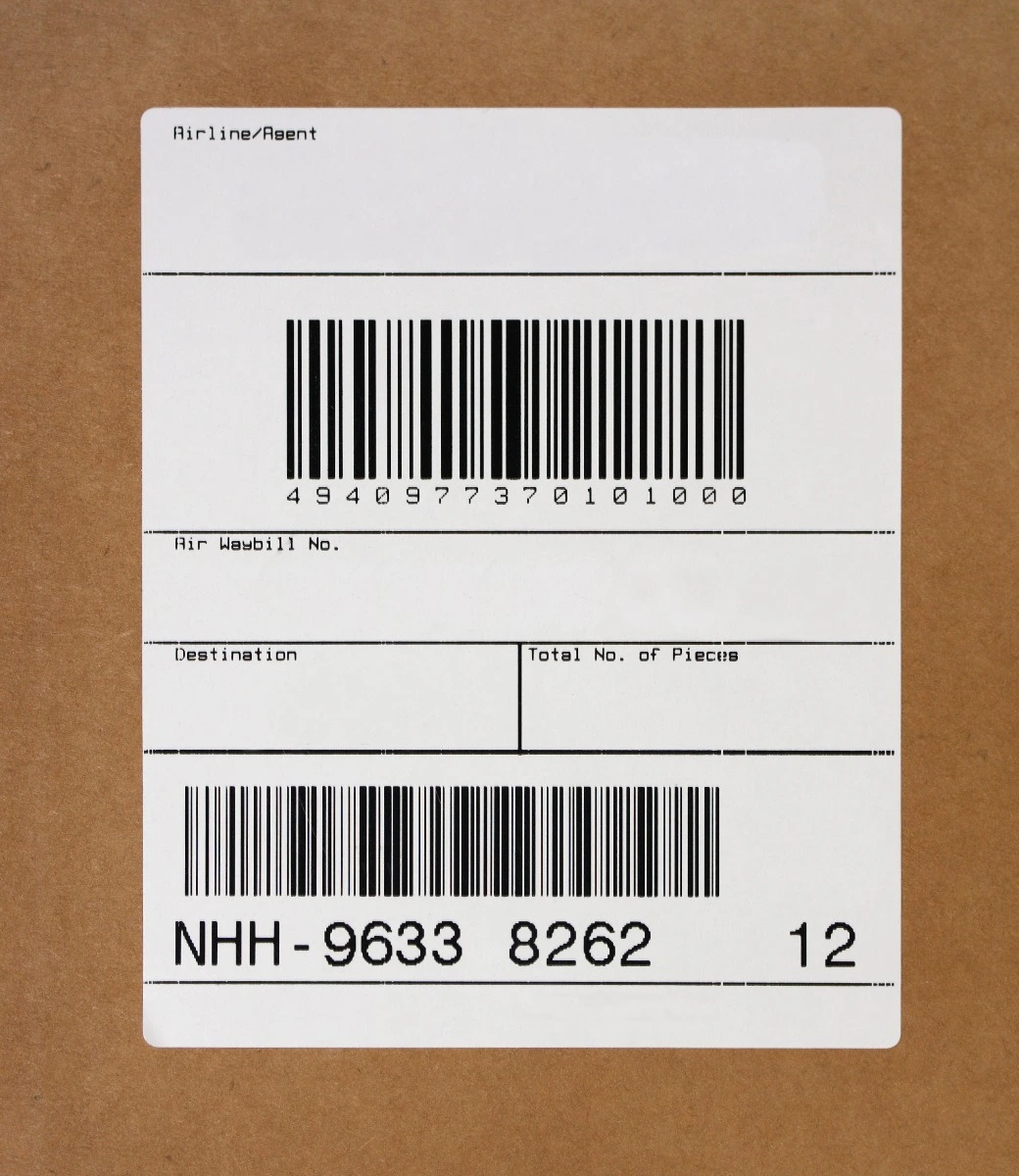

A printed label is the key component for items that need to be identified quickly and easily. If a product or item needs to be identified quickly and efficiently, a printed thermal barcode label offers the best route for your business. From low volume printing to large scale enterprise global solutions, the barcode label is the key for your success and productivity.

Printing barcode labels requires an easy system setup. This system will have three (3) main components: the printer, the labels and ribbons, and the software/scanner. Additionally, your business size, the volume of printing you demand, and the item that you want to label all influence which system will work best for you. No matter the size or the item, the barcode system is designed to streamline your productivity.

The advantages of using barcode thermal labels are endless, especially if you’re using them for inventory marking, distribution and shipments, asset tracking, and more.

ADVANTAGES OF BARCODE LABELING

Barcode labels are a viable and efficient choice for business to improve productivity and to reduce expenses...which is another way to say that you can save time and money. Here are a few ways that you might use barcodes to reach those goals:

-

Let’s start with money -- barcode use is inexpensive and practical. You can even find free barcode generators online. Beyond the initial time factor included in barcode setup, you’ll learn that barcode use actually saves money when compared to one-off labels. They can be customized economically in a variety of finishes and materials.

-

The cost of human error can be an annoyance or horrific. For instance, a human error in transcribing information for medical purposes could be tragic. On the other hand, accurate inventory can save you money by reducing over stocking to account for that human error. Human error in data entry is, perhaps, the costliest error for businesses. Reduce that cost with barcode labels.

-

Learning about Barcodes is easy and it only takes minutes to learn how to use a handheld scanner compared to hours learning about a company’s inventory. That knowledge is not necessary when using barcodes. Therefore, you’re saving a ton of time and cost in employee training.

-

Barcode technology is versatile and adaptable. You can attach barcodes to any surface, completely streamlining not only your inventory but also your office equipment, outgoing shipments, and incoming inventory.

-

You can use one barcode for both inventory and pricing information, so the task of accounting for inventory and cost becomes streamlined. You can, with barcodes, quickly obtain information on both criteria. Further, you can customize barcodes to include any other information you’d like to see.

-

Data obtained through barcodes is available in the blink of an eye. Since the information is scanned directly into your central computer, it is ready almost instantaneously. This quick turnaround ensures that time will not be wasted on data entry or retrieval.

-

When you receive instant information on inventory, cost, and other data, you can make better business decisions. No more waiting around for number crunching with barcode technology at your fingertips.

Depending upon the application, time savings can be significant. Often the most dramatic examples involve the ‘beloved’ chore of taking inventory. One customer needed a crew of 25 employees working over a weekend to take his annual six-month inventory. When he switched to barcodes, he reduced his inventory staff to to four employees and the inventory time to a total of about five hours.

Even in routine day-to-day operations, barcode use time savings add up quickly to improve productivity. When comparing a hand-written compilation of information on outgoing merchandise to the same merchandise that is stamped with barcodes, you can see a significant improvement in time, cost, and productivity. In any business, this ability to save time and money is a plus.

Barcode printing is the go-to technological method that many companies around the world use for shipping products, controlling and improving inventories, and ease of data management. Barcoding technology is user friendly. Anything that you can use to easily ship your products, control or improve inventories, and make your data management easier is a friend to your business, too.

TURN YOUR BUSINESS AROUND

If you look this information up online, you’ll find the facts everywhere: The typical error rate for human data entry is 1 error per 300 keystroke characters. Barcode scanners are much more accurate; the error rate can be as minor as 1 error in 36 trillion characters depending on the type of barcode used.

Clerical and data entry errors can prove a significant source of costs and related problems. Extra freight costs, unhappy customers, and time spent to track down problems are just a few examples of problems that can eat into your budget. In some situations, clerical errors can have a much more dramatic impact -- consider the importance of accuracy in pharmaceutical or blood bank applications.

Additionally, you can use barcodes as effective tools to address specific, localized problems or issues that integrate into organization-wide information systems. When applied with thought and planning, barcodes can save time and reduce errors, resulting in a reduction of costs.

Finally, regulatory agencies or your customers may impose labeling requirements that you must meet. While these requirements may be a necessary part of doing business, you can save time and money by utilizing the barcodes within your own operations. For example, you can collect shipping manifest information quickly and accurately by scanning the barcode labels that you printed to satisfy the customer.

THE BARCODE LABEL DEBATE

You may have come to the debate where you consider the value between using pre-printed labels from a third-party source versus on-demand printing with their own barcoding system. Pre-printed labels are useful when your application requires only a few identical labels, often with multiple colors or graphics. However, companies that start with pre-printed labels quickly discover their limitations.

The solution is simple: Besides restricted flexibility, the use of pre-printed labels prevents companies from including variable data in their labels, thereby reducing their information base. Most companies find the commitment of on-demand and in-house barcodes worth the initial investment because of the added value from printing customized information on each label.

Thermal printers offer the best solution for barcode printing, when compared to laser or inkjet printers. Thermal printers offer lower cost of ownership, and true one-off on-demand precision printing for easy scanning. With the barcode label being such an integral part of any system, you want to ensure it is clearly printed with no bleeding to ensure even the simplest scanner can get good reads.

THERMAL TRANSFER AND DIRECT THERMAL LABELS - the difference

Very simple: one uses a ribbon and heat to print, the other uses a coating and heat. Read more about the differences between thermal direct and thermal transfer label printing and how to choose the right method for your application.

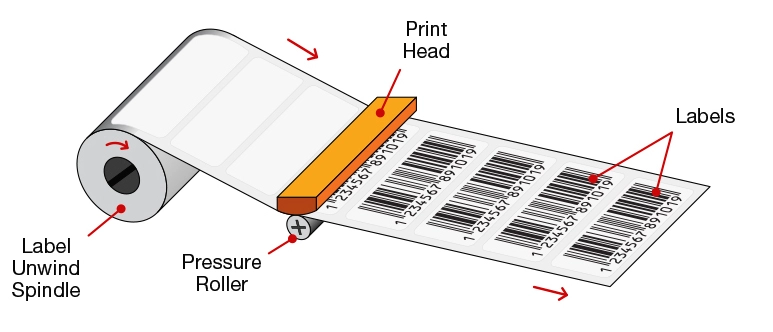

How Direct Thermal Printing Works - a simple explanation

This method uses heated print head to create a chemical reaction within the label itself. This reaction creates the printed scannable image. The only media that passes through the printer is the printable adhesive label paper. The chemical composition of the label paper and the thermal print head is all what is required.

Illustration of direct thermal printing

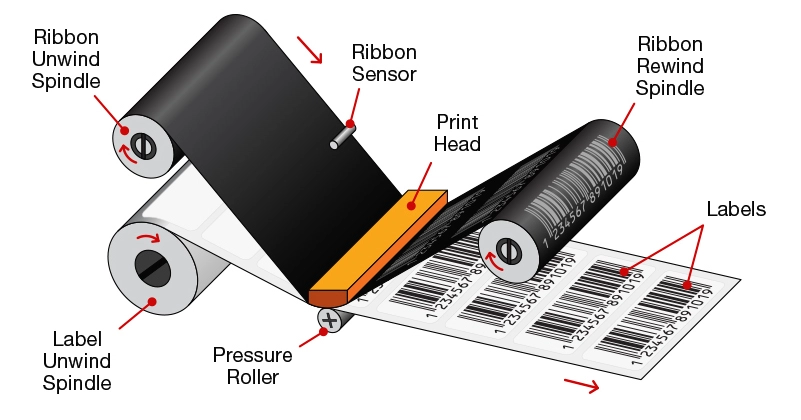

How Thermal Transfer Printng Works - a simple explanation

This printing method uses a hot print head which melts a wax ribbon onto the blank face-stock of a printable label. Paper or film media and a ribbon is required. The type of media and ribbon will depend on the appllication. This method result is a durable, permanent high quality scannable print

Illustration of thermal transfer printing

WHAT ARE BARCODE LABEL PRINTING SYSTEM COMPONENTS?

All label printing systems consist of 3 core components:

Barcode Printer - This is your major investment in this project, as a unit with the correct features is critical to barcode printing. Your options depend upon how much printing you’ll need to do, and if you need to be mobile or fixed in your location. Options such a interfaces, cutters, peelers, and embedded fonts all work to ensure the best configuration for your application.

Labels and Ribbon - The only criteria involved here is to make sure your labels and ribbon match your printer model to ensure the best quality print with minimal effort.

Barcode Software - Finally, you need a way to tell the printer how to use the ribbons and labels to create your barcodes. Label design software ranges from extremely simple to fully automated print servers that pull information from a database.

IMPROVE OPERATIONAL EFFICIENCY NOW…

Now that you’ve made the decision to check out how barcodes can streamline your business, you can use this article to ask questions about how to use barcodes to provide faster and more accurate tracking information. If you need further information about your choice of a barcode system, please feel free to contact us at:

How Can We Help You Further?

- Need to find low cost alternatives to Zebra labels

- Maintance for your Printers will save you lots in the long run

- Learn more about Thermal Labels and Barcodes

Please contact us for more information on thermal labels, would you like to test our labels, free thermal label samples are available on request.